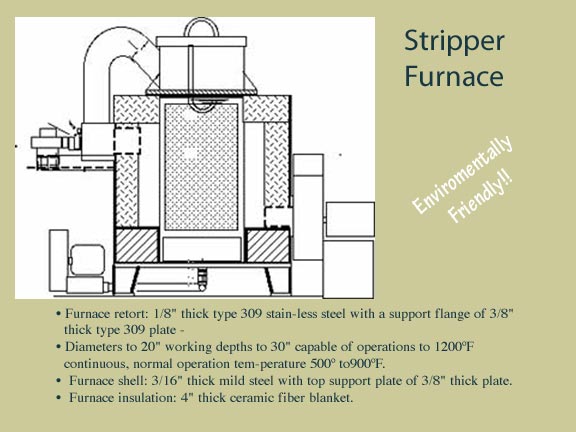

Cleaning/Stripping

Why select an enviromentally friendly Fluidtherm furnace?

A fluidbed, , by itself, can provide heat and some mechanical working of parts to effectively clean residue and provide a workable salvaged part. The fluidbed will, however, generate copious fumes from the hot combustible hydrocarbons that are the subject of attack. The choice now is to live with these fumes until they dissipate, (not at all healthy), collect the fumes and blow them over the neighborhood (healthier for the workers, however, not good for the environment nor for the public relations of the company), pass the fumes through a treatment scrubber to remove the soluble gases and solids (that will leave a liquid waste for disposal), or incinerate the fumes (best idea since a suitable treatment will result in converting all of the gases and flyoff residue into CO2 and H2O). The Fluidtherm solution for treating the fumes is the incineration route since this will cause no one harm due to dirt or noxious fumes. We suggest that the heat developed can be used for practical purposes and we have designed a fluidbed unit that will be heated with the by-product gases of the incinerator. The design incorporates a gas burner system that operates under excess air conditions.

The hot gas discharges from the incinerator directly into a fluidbed furnace heating chamber. This utilizes otherwise wasted hot gases and cools the gases for venting directly into a flue pipe and to the atmosphere. The gas is as described above, harmless CO2 and H2O and is colorless. Since the incinerator will be located adjacent to the furnace to keep a short compact discharge pipe, a similar feed tube from the fluidbed to the incinerator intake is incorporated near the furnace top to guide the noxious fumes from fluidbed to incinerator.