Salt Bath Production

Lightweight transmission parts for automotive, lawn mower blades, crank shafts.

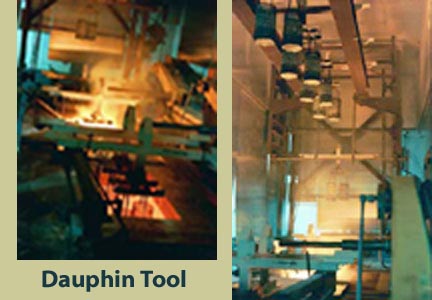

Tapping tools are basket loaded and transferred through our system to harden these tools overall. Typically the austenitizing temperature is 2250º F, and Quenching at 900º F. Almost all systems have at least one preheat to approx. 1400º prior to the austenitizing furnace. This system also has a post cleaning operation that involves a multi-cycle soak in hot agitated clear water, and a finish rinse in ultrasonic agitated acidic water. After the heat treat cycle, the parts are air cooled for approximately one hour. The entire operation is automatic from a load accumulator conveyor through the processes and back. Temperatures, and conveyor cycling is controlled with state of the art process controllers.