Why a Fluidbed?

Application of salt bath equipment has started to diminish but the demand for the quality of case hardening that was available from salt has not disappeared. In fact, most material used in the present day manufacturing have been improved by heat treatment to utilize all of their inherent strengths. These strengths are augmented by the use of the carburizing for enhanced toughness and nitriding for enhanced wear resistance.

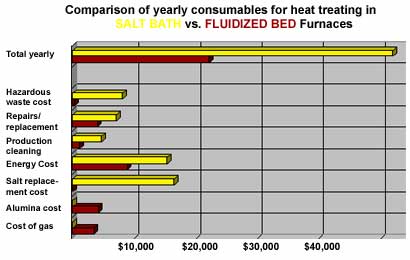

A fluidbed can now be used in the place of a salt bath yielding similar heating speed rates, while temperatures range from ambient to 1950ºF. It can be used for neutral heating one minute, and with a simple operation be converted to carburizing in the next minute. It can be operated at any desired temperature continuously and then shut down at the end of the heat treating period, thus drastically reducing utility costs.(See comparison chart below)

Heat treating is time, temperature and environment, but there is a fourth factor of experience which sometimes becomes the most elusive factor. The experience to learn how to use a furnace so fast, clean, safe, versatile and economical is more than enough reason to investigate a fluidized bed furnace.